Overview of Lean Management

By reducing wastage of resources including time, money, and effort, lean management is a corporate practice that aims to improve quality and efficiency. Lean manufacturing and lean production are some names for it. The goal is to provide consumers and clients with just the greatest and most value services or products at a fair price.

Lean Management History

The Toyota Production System served as the foundation for the lean management idea in the Japanese industrial sector in the 1990s (TPS). Toyota began as a little automaker but gradually rose to prominence on a worldwide scale. As a result, its business model and operating procedures were swiftly adopted. Soon after, other businesses started to implement comparable approaches in an effort to experience the same degree of success. Leading companies today, like Intel, John Deere, and Nike, adopt lean management extensively.

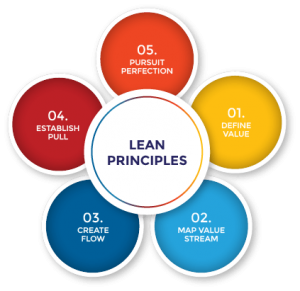

Fundamentals of lean management

These fundamental ideas-defining value, mapping stream value, producing flow, building pull, and achieving perfection-are at the heart of lean management.

Indicating Value

From the viewpoint of the client, this concept indicates the value of a good or service. Rotating Solutions emphasizes the value of developing and concentrating on a production schedule that includes delivery. Detailing important specifications, pricing ranges, expectations, and other key information might be included in this.

Value Stream Mapping

This idea is often referred to as trash mapping. It analyses each stage of a particular business process to identify any extra procedures or resources that may be cut out to increase efficiency.

- Developing Flow

This approach focuses on achieving efficiency and speed while also making sure that several operational duties are accomplished as fast and without hiccups as feasible.

- Developing Pull

Establish a process where there are just enough materials and resources available to produce the desired goods on schedule and continuously.

- Trying to be perfect

Actually, this refers to ensuring that the other four principles are used continually and reliably. Ensure that the overall lean mission is shared by every employee.

The next five stages, which complement the fundamental ideas, offer another perspective on lean management. These are referred to as the “5S” and are listed in Japanese as follows:

Seiri (organization)

Seiton (order)

Seiso (cleanliness)

Seiketsu (standardization)

Shitsuke (discipline)

Lean Management’s advantages

Continuous improvement is the common objective of businesses that use lean management practices. They frequently achieve this aim by putting these lean ideas into practice since they save time and money. Additionally, they can raise client satisfaction levels, which may result in more money from repeat customers and recommendations.

Learning lean management techniques might also be a wise investment. Students who complete our Lean Management Certification Training program learn vital lean management skills that will not only help them succeed in their present positions but also in other possibilities they may pursue in the future.

Students learn about all facets of lean management in this training program, as well as how these ideas may be used in service, manufacturing, and general business positions. Students gain knowledge of the numerous lean management tools, typical waste kinds, and strategies for eliminating waste to increase overall corporate efficiency. This course offers five hours of online instruction, a downloadable e-book, and additional tools that are beneficial to learners of all ability levels. Students receive a lean management certification after finishing.